HRP Benefit #3Best in Class Reliability

HRPI offers proven results with hardened technology since 1987. We don't supply commodity products, we provide engineered solutions custom tailored to your needs because no two wells are alike, just like customers.

Our product development focus has been on the below 3 key areas:

- Realiable Performance

- Maximise Uptime

- Innovative Industry Leading Products

That is why we have units running since our founding days 33 years and counting, in the some of the world's most senstive areas that can't afford constant downtime.

We Use What We Sell

HRP was founded by an indepedent producer to resolve problems other hydraulic pumping unit manufacturers were unwilling to address. Our dedication to maximizing reliability stems from our first-hand knowledge & experience that breakdowns & down-time were absolutely critical to profitibaility costing lost production in addition to repairs.

Decades of trial-and-error; Methodically researching options; Implementing rugged, robust solutions in incremental steps, created a packaged solution unlike any other competitor on the market with options second-to-none.

Our knowledge & expertise runs deep, we solve the problems where all others have failed.

Hydraulic Cylinder Reliability

Our direct-mounted cylinder's seals are the most critical feature on our hydraulic pumping systems. Ask any field engineer (operator) about SRP stuffing box seals and most will complain about repeitive, constant nuissance leaks. We learned the hard way across hundreds of wells spanning several decades that failures are caused by several different factors, so you don't have to.

Elastomer science has progressed since Goodyear vulcanized rubber in 1839. It's easy to make mistakes when selecting elastomers and this is where most competitors fall short. To resolve these issues we use different elasotmers for different environments, with temperatures and applications. There are no panaceas, but there are secret recipes to designing cylinders with seals than can last longer than a decade.

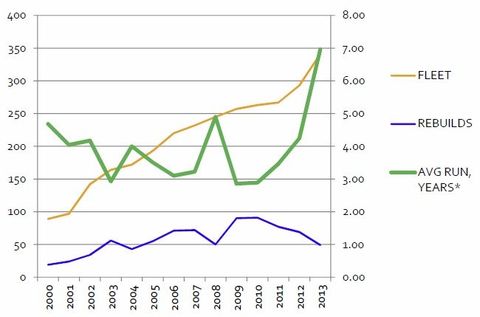

MTBF: In a study conducted in 2012 throughout the Los Angeles fleet, averge life-expectancy for integrated stuffing boxes (polished rod seals) showed average run-life exceeded 3.8 years. This MTBF statistic even includes non-failures, where cylinder rebuilds were triggered by downhole failures (Note: The risk-cost & logistics in moving a rig over many wells to exchange a cylinder far outweighed the cost of a seal rebuild, so operators regularly rebuilt cylinders with nothing wrong with them).

Power Unit Reliability

The oilfield operating environment is often brutal & harsh, beyond measure. If equipment isn't running 24 hours, ~365 days a year, it's considered nearly worthless.

That why we say "Run Time Is Everything".

We've integrated more knowledge & features, gathered intelligence over more years than all of our competitors combined. Component metallurgy; Circuitry design; Software Engineering; Electrical & Mechanical Fail-safes; Crippled (limp) operating modes; Self-healing operating modes; Resilient Cooling system modes; Early-Warnings via Remote Telemetry.

All of our features & specifications have a purpose, stemming from our experience about failures & how to prevent them or at minimum, extend run-times out to as long as possible between repairs.

If our customers weren't pleased with their long-term results, we couldn't say we're the oldest surviving hydraulic pumping unit company, in the history of of this business.

What About Leaks?

We designed our units to be easy to maintain & repair with unique features to counter the issues everyone hates about hydraulics: OIL LEAKS.

We deployed a technique of locating as many hydraulic components as possible inside the oil reservoir to minimize nuisance leaks. This technique minimizes leak-points and risk to the outside environment. We went even further by leveraging our knowledge about metallurgy, mechanical design & seal elastomers to reduce the risk of leaks everywhere possible.

We've successfully blended API, Fluid Power & Aerospace technology to help prevent leaks from ever occurring and when the unexpected happens, contingency plans have already been considered.