Artificial Lift Comparison

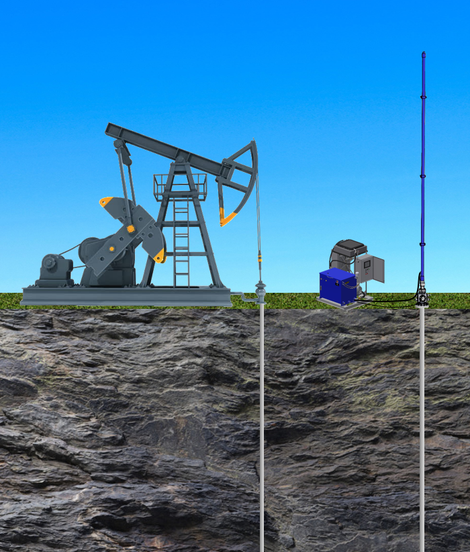

Hydraulic Rod Pumps, International (HRPI) manufactures several types of hydraulically actuated sucker rod pumping units for use on oil and gas wells. The most common type of HRP (Hydraulic Rod Pump) currently used throughout the world is an above-ground type, with a tower-mounted hydraulic cylinder (typically possessing a 120” stroke length), and is actuated with a noncounterbalanced power unit.

For purposes of this discussion, the following associations are made between the stroke length of the unit and the category of pumping unit; short stroke=120”, long stroke=240” and ultra-long stroke=336”. While HRPI offers a broad spectrum of pumping unit solutions, this discussion is focused only on comparing the differences between long (or ultra-long) stroke HRP units and other artificial lift technologies.

HRP vs. Traditional Beam Units

Traditional beam units are the most utilized and durable artificial lift method. HRP technology merges the traditional benefits of a rod pump with new technologies to address the flaws in traditional beam unit rod pumps.

NO ROD STRING COMPRESSION

- HRP units never induce a downward force on the polished rod

Near Linear Polished Rod Velocity

- Lower Peak Polished Rod Load (PPRL) results from eliminating rod string acceleration/deceleration

- Increased pump efficiency

Long Stroke

- Reduced wear

- Less pump cycling

- Increased pump efficiency

- Deviated Wells

Low Profile

- Easy Workover

- Dense Well Spacing

- Below-grade installation

- Remote Optimization & Monitoring

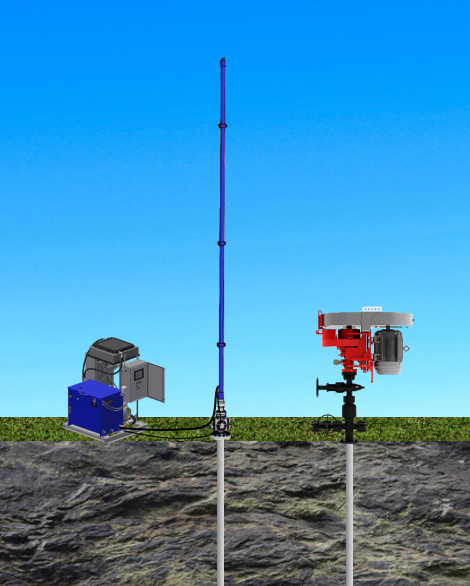

HRP vs. Progressive Cavity Pumps (PCP)

In wells less that 5000 feet, Prograssive Cavity Pumps (PCP's) are generally considered an attractive solution because of high electrical efficiencies and low capital costs.

PCP's are not cost effective under certian well conditions such as heat, chemicals, sand/solids, and high Gas to Oil Ratios (GOR). Rod pumps are relatively unaffected by all of these adverse conditions.

We have had great success replacing PCP's with HRP's in a number of wells in the Los Angeles Basin.

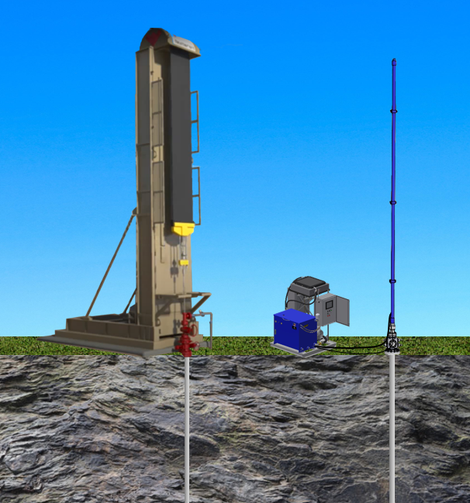

HRP vs. RotaFlex®

The RotaFlex® is a 100% mechanical long-stroke slow stroke surface drive pumping unit used to lift crude oil from deep or high volume wells. The patented design is 20%-30% more electrically efficient than the conventional beam pumping unit. The unit provides a 306-inch pump stroke and has a fixed traveling speed that can result in longer run life of the down strokes equipment. The reversing mechanism is completely mechanical and creates a 306-inch pump stroke.

The principal application for the RotaFlex® product is oil wells that are 8,000-10,000 feet in depth where the unit can pump 300-800 BPD at up to 4.5 strokes per minute versus 10-12 strokes per minute required in a conventional rod pump unit. The slow speed significantly reduces tubing and rod wear and improves electrical efficiency. The other application for the RotaFlex® unit is in wells that require larger pumping volumes than conventional beam units are capable of producing.

HRP units are applicable on nearly all wells where RotaFlex® units are appropriate. HRP units provide the added benefit of a low profile wellhead. During workover, both Above Ground and Subsurface Hydraulic Cylinders are easily and safely removed, whereas a RotaFlex® unit moves, but remains largely in place.

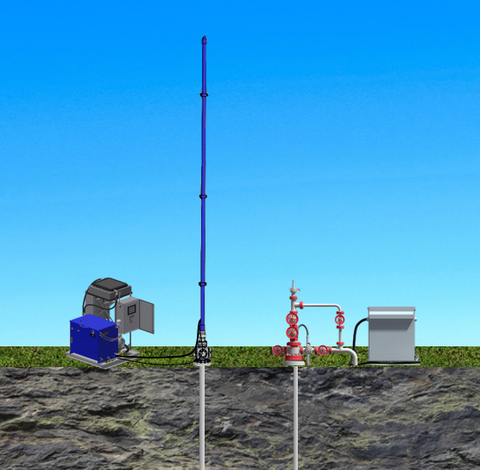

HRP vs. Gas Lift

In wells less that 5000 feet, Prograssive Cavity Pumps (PCP's) are generally considered an attractive solution because of high electrical efficiencies and low capital costs.

PCP's are not cost effective under certian well conditions such as heat, chemicals, sand/solids, and high Gas to Oil Ratios (GOR). Rod pumps are relatively unaffected by all of these adverse conditions.

We have had great success replacing PCP's with HRP's in a number of wells in the Los Angeles Basin.