About Hydraulic Rod Pumps, Intl.

Hydraulic Rod Pumps International, founded in 1987 in Southern California is the world leader in hydraulic rod pumping technology. For more than 3 decades we've focused on and developed the world's most durable and advance Hydraulic Rod Pumping units. Our technology & equipment is field-proven and had been highly successful in delivering ultra-reliable performance for producers worldwide.

Today's volatile energy markets have prompted producers to demand the latest available technologies, higher electrical efficiencies and more reliable products from vendors across the board. Requests of this nature have become the new standard throughout today's E&P supplier marketplace, as producers prepare for an unpredictable revenue stream. Artificial lift is the primary tool for generating revenue and the largest area of expense for producers, so it has become the primary focus for maximizing efficiency and equipment longevity.

Ultra long-stroke sucker rod pumping units entered the scene in the 1970's, as prototype experiments. They've emerged in the last decade as one of only a few quantum leaps in artificial lift technology throughout the entire history of sucker rod lift. This technology has quickly become the new standard, frequently chosen to solve problems, lift more fluid, reach out farther horizontally or go vertically deeper than any conventional beam unit can go.

How?

- Slower traveling speeds = reduced rod string fatigue.

- Near-fixed traveling speeds = lower rod string compression.

- Slower strokes per minute = reduced traveling/standing valve wear.

- Longer stroke lengths = higher compression ratios, which helps reduce gas locking.

- Longer stroke lengths = better mechanical efficiency (stroke vs. stretch ratio).

- Longer stroke lengths = longer tubing life due to longer coupling-to-tubing wear patterns.

- Ability to lift larger pump plungers = higher volume rate capacities.

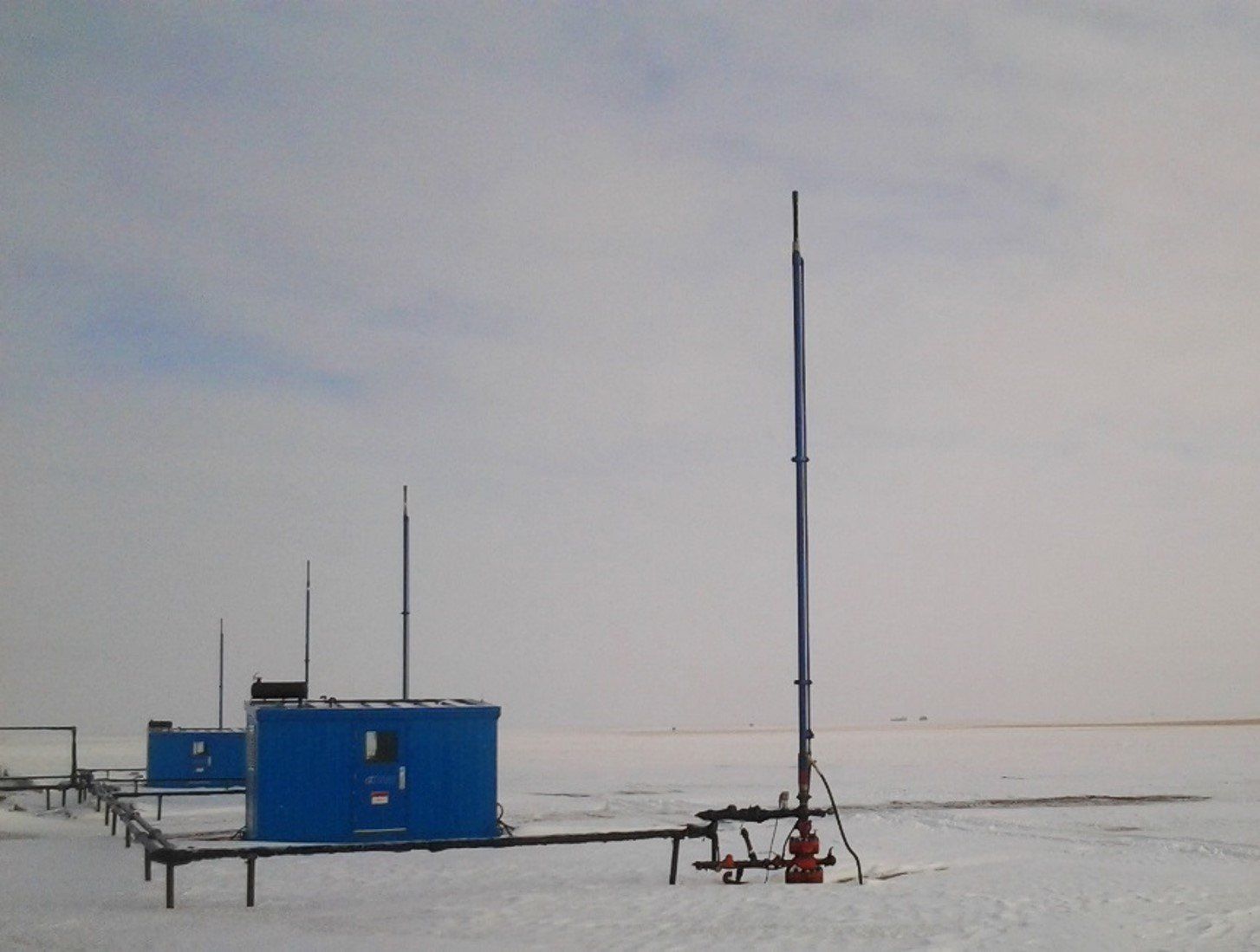

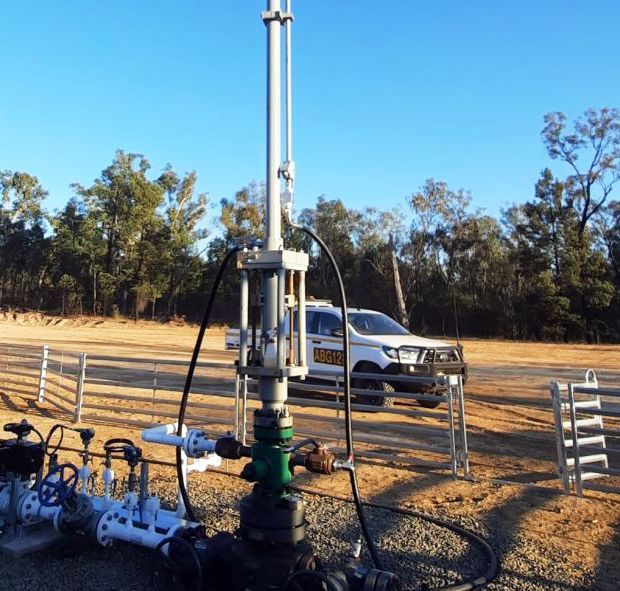

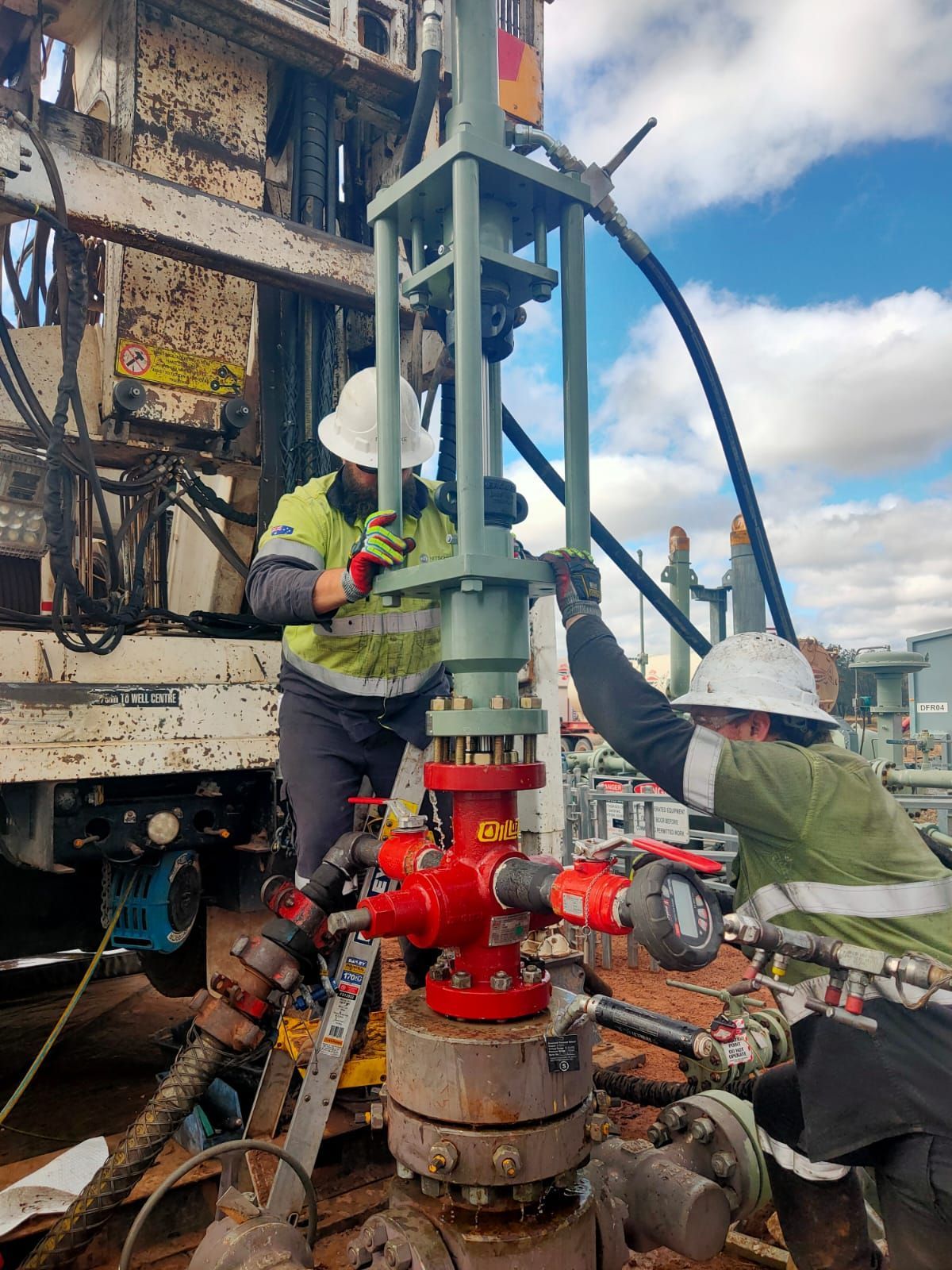

Some of our installations

HRPI's role in this evolutionary process has been to develop leading-edge ultra long-stroke pumping unit technology and to provide producers with proven, innovative solutions. Our product line has been designed to specifically addresses concerns about electrical efficiencies, capital costs and restricted-location issues that so many producers face in today's oilfields.

While hydraulic rod pumping unit technology is more than 50 years old, it has yet to become a widely accepted lift method due to the mistakes of the many ill-equipped manufacturers who improperly designed and deployed fluid power technology. Most of our predecessors (now mostly forgotten) failed to employ sound engineering principles, whether it be as simple as a metallurgical refinement, or an entirely new component model design. The fluid power industry has worked hard over the last 50 years to improve quality, reliability and efficiency, while the technology and industry has been globally unified by the advent of the International Standards Organization (ISO).

Hydraulic Rod Pumps Int'l succeeds where most have failed by employing sound engineering principles and testing them over long term.

HRPI's focus continues to be on providing quality products with an equal emphasis on field service.

We strongly believe in properly testing all new products before widespread release to the public, to ensure that our customers receive only reliable equipment.

Here's a partial list of the features and benefits we've packed into our products:

- Ultra long stroke lengths (up to 336 inches or 28 feet) reduces tubing wear and pulling costs.

- Lower capital cost (less expensive than beam units, ESP's, Kobe Hydraulic, etc.).

- High reliability (99.7% up time average).

- Phenomenal efficiency (better than beam pumping units).

- Computer enhanced (remote telemetry, dynamometers & pump off control).

- Polished rod lifting capacities exceeding that of beam units.

- Low vertical profile (see our cornerstone, Subsurface hydraulic cylinders).

- Semi-portable hydraulic power units (weighing less than 8,000 lbs.).

- Low maintenance costs (proven).