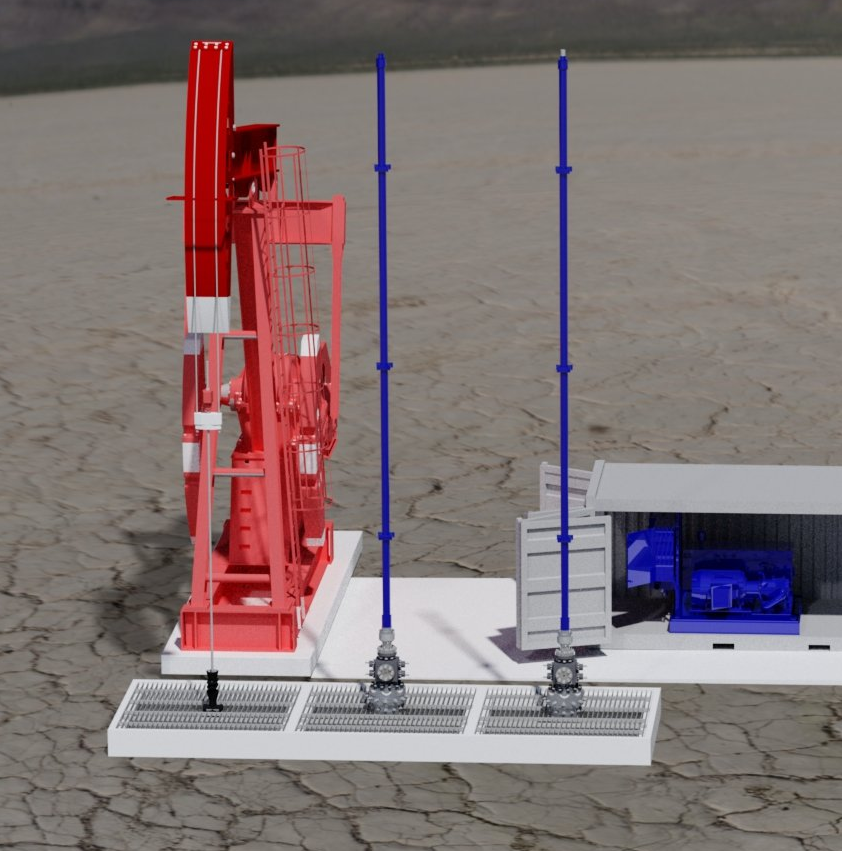

Above Ground

The most advance hydraulic rod pump cylinder in the industry, boasting a maximum stroke length of 336", a proven integral sealing system and sturdy construction.

Features & Benefits

HRP International's Above Ground Hydraulic Cylinder boost the longest stroke length in the industry at up to 336 inches. The cylinder's advance sealing technology is also a world's first, installing directly above the pumping tee and eliminating the need for a stuffing box.

The Hydraulic Cylinder's construction is sturdy and light and don't require a pedestal on the well head for installation. Guide wires are not required to stabilise the cylinder. We use an optional tripod stabilizer to limit sway / harmonics.

The Hydraulic Cylinder also withstands high winds up to 60 knots and are installed in areas that experience cyclones and hurricanes. It is compatible for harsh produced fluids (acid, steam, condensate) and requires no special well head or adapters.

HRP Hydraulic Cylinder

Features & Benefits

Specifications

We have a wide range of cylinder sizes & stroke lengths to cater for most applications.

Stroke Length

36, 60, 86, 120, 240, 336 (inches)

Cylinder Sizes

2.5, 3.0, 3.5, 4.0, 4.5. 5.0 (inches)

Peak Polished Rod Load (PPRL)

up to 53,376 lbs

Design Pressure & Temperature

design pressure 5000 psi

design temperature 150 deg C

Cylinder Sizes & PPRL Ratings

| Cylinder Size (Bore x Stroke) | Max PPRL (@ 3000 psig) | Extended Length | Collapsed Length |

|---|---|---|---|

| 2.5" x 240" | 12,363 | 527" (44') | 287" (24') |

| 3.0" x 240" | 18,840 | 527" (44') | 287" (24') |

| 3.5" x 240" | 25,169 | 527" (44') | 287" (24') |

| 3.5" x 288" | 25,169 | 623" (52') | 335" (28') |

| 3.5" x 366" | 25,169 | 719" (60') | 383" (32') |

| 4.0" x 240" | 34,000 | 527" (44') | 287" (24') |

| 4.0" x 288" | 34,000 | 623" (52') | 335" (28') |

| 4.0" x 336" | 34,000 | 719" (60') | 383" (32') |

| 4.5" x 240" | 42,390 | 527" (44') | 287" (24') |

| 4.5" x 228" | 42,390 | 623" (52') | 335" (28') |

| 4.5" x 336" | 42,390 | 719" (60') | 383" (32') |

| 5.0" x 336" | 53,376 | 719" (60') | 383" (32') |