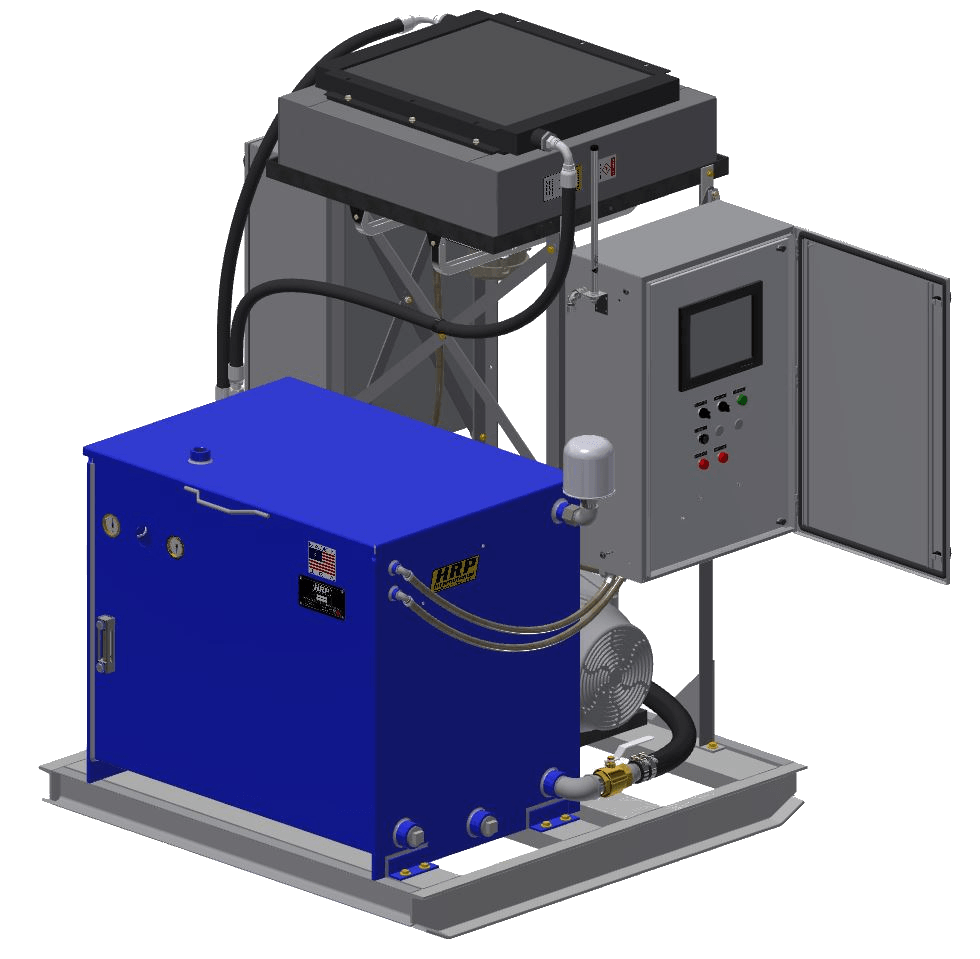

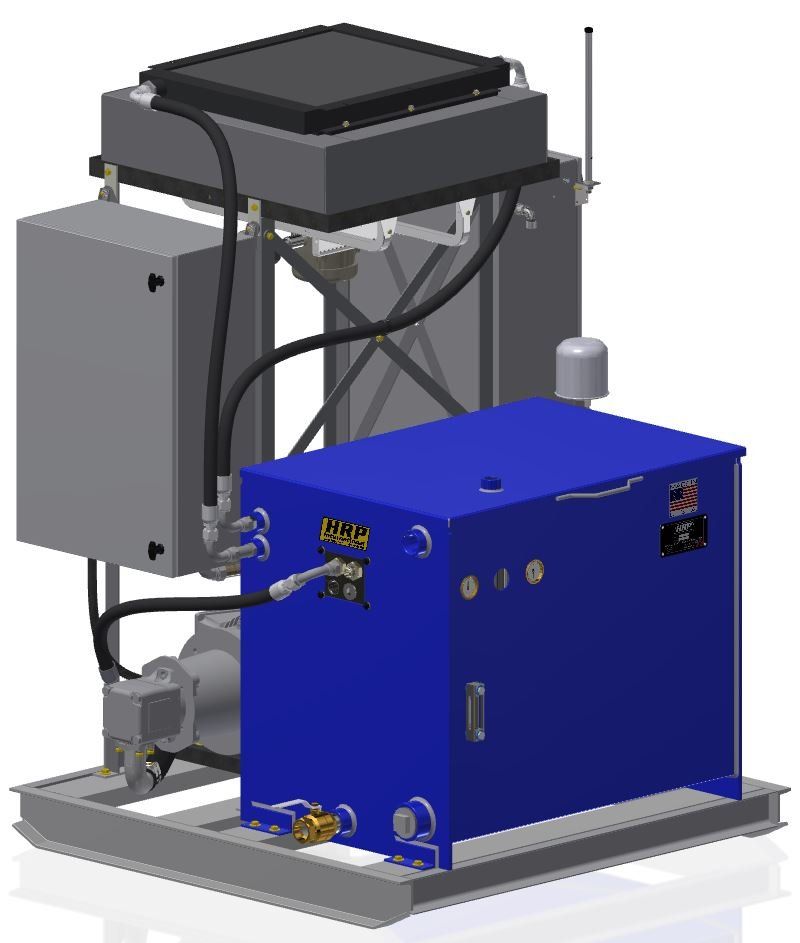

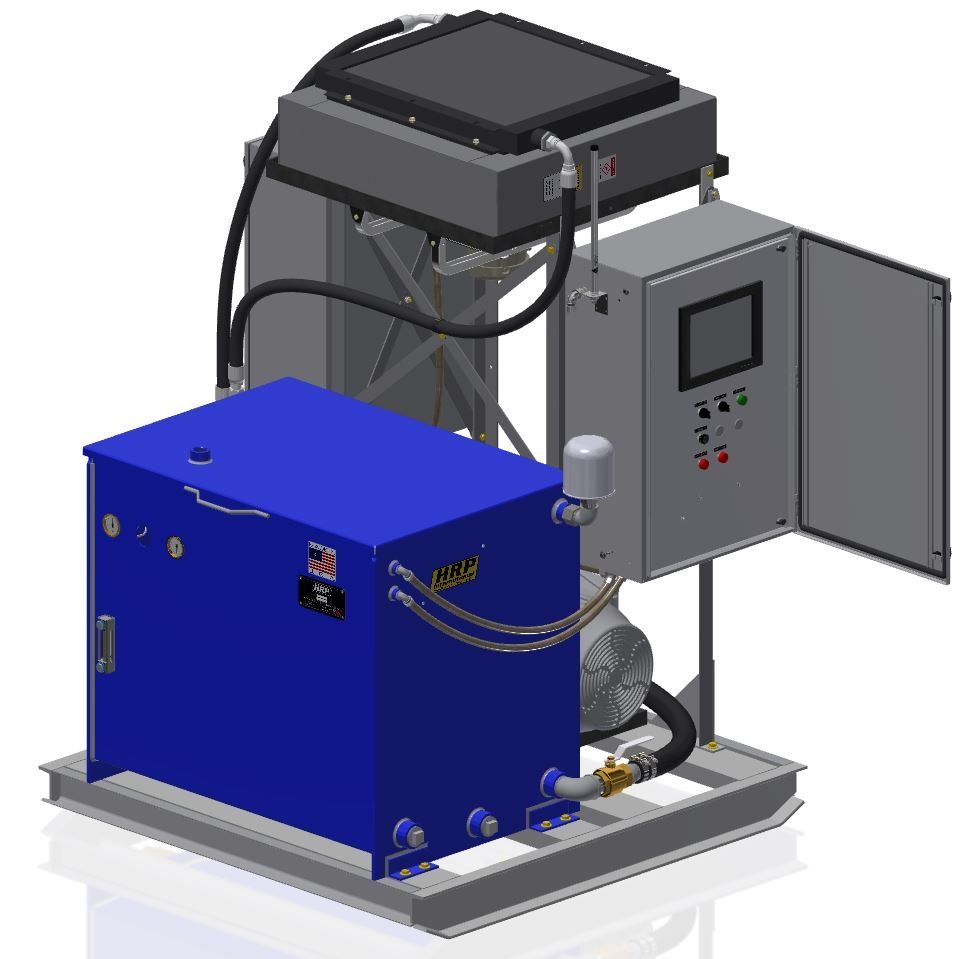

HRP

Hydraulic Power Unit

Advance, Intelligent and Compact all in one package that is field proven, tested and improved for over 33 years.

Features & Benefits

HRP's Hydraulic Power Unit (HPU) is a compact, intelligent and advance all in one package that includes the hydraulic pump, prime mover, hydraulic valves, cooling system, oil reservoir, motor controller and PCL pump controller on a bunded skid.

Our HPU is designed with simplicity, robustness and trouble-free in mind. We've been improving on our design over the last 33 years and had incorporated the latest innovation in hydraulic technology. Our HPUs are capable of single and dual-well operations, and had been field tested and proven to outperform and outlast competitors. We welcome challenges and thrive on engineered and customized solutions, there is no application too difficult for us.

HRP Hydraulic Power Unit

Features & Benefits

General Specifications

Our Hydraulic Power Unit (HPU) comes the following prime mover options:

Electric Motor, Diesel Engine, Gas Engine

Power (HP)

10 - 150 HP

Hydraulic Pressure Rating

Vane Pump: 3000 psig (continuous)

Components: 5000 psig

Reservoir Capacities

60, 100, 200 US Gallons

Operating Temp

design temperature 180F (80C)